E-Scrap Plastic, the Next Challenge in Recycling

Published March 2019

New Challenge in E-Waste

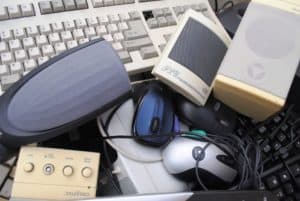

As an environmental partner offering our customers responsible outlets for recycling their regulated waste, we run into many challenges as regulations and markets change. Over the last few years, we have seen challenges in the processing of leaded CRT glass from tube televisions and monitors. A new challenge in the E-waste recycling market is upon us, and that is plastic.

In the U.S., over 25% of the items received by a recycler will be e-scrap plastic. In Europe, that number can be as high as 80%. The value of the plastic is often not worth the labor to attempt to separate the material. Plastics found in TVs, computers, and printers has little to no value. Mixed plastics are one of the least valuable materials and most common material streams, so often times they end up in toxic graveyards, overseas. This needs to stop, and many places are no longer accepting this waste due to the various challenges with the materials. The volume alone will likely lead to stockpiling, as we have seen with CRT glass.

Why is E-Scrap Plastic So Hard to Recycle?

The shredded mix of e-scrap plastics is one of the hardest plastics to recycle due to the mixture of polymer types. If you recycle a water bottle you may have only two or three polymer types; with e-scrap shredded plastics there could be over ten polymer types.

Brominated flame retardants (BFRs) have also been a historical barrier. Besides effecting the environment and the potential hazard to people and animals, they increase the cost to recycle.

Going Forward

Regulators have recognized this issue, and have been working to push manufacturers for a solution. The MPCA is working on a program with objectives that include supporting electronics product stewardship efforts, identifying opportunities and barrier to closed-loop recycling of plastics from electronics, and determining how recycling these plastics might reduce the production of greenhouse gases.

Scientists at the Illinois Sustainable Technology Center, have discovered a way to separate mixed polymers, to allow all plastics in e-waste to be recovered, although it is not yet being done on a large scale.

What’s Next?

With such a wide-spread issue, and various projects cropping up in the early-development stages to address these issues, we can expect to see some successes and some barriers as things continue to change. With stockpiles, you can likely expect to see price increases, as you have seen with CRT processing issues and stockpiles.

You are encouraged to work with a partner that you trust is properly handling and recycling all of your waste streams. If you have questions about where your waste is going and how it is being processed, don’t hesitate to ask. Any qualified recycling partner will be able to answer, in detail, exactly how your waste is being handled from start to finish.