Customer Spotlight – Crown Plastics

Published August 2018

4 REASONS WE DECIDED TO UPGRADE OUR LIGHTING

1). “TO INVEST IN OUR EMPLOYEES”

They say a company will never succeed without being employee-centric, and this is the approach that Matt Van Beusekom, Operations Manager at Crown Plastics, Inc., fully believes in. Taking pride in this family business not only means pleasing the customers, but it also means taking care of their employees and providing them with an excellent place to work.

2) “WE NEEDED LIGHT”

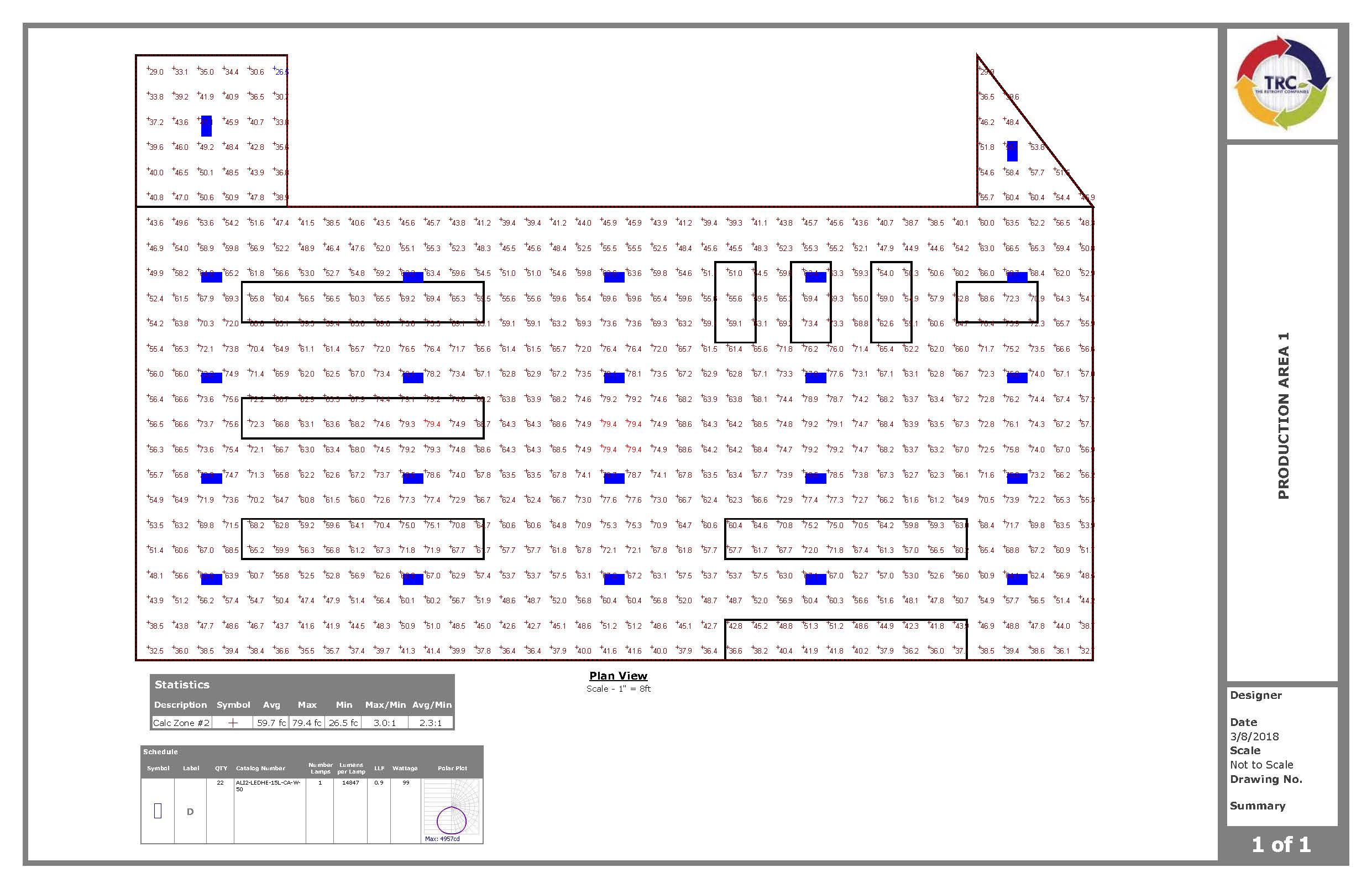

As with any business, Crown Plastics, Inc. has a variety of areas throughout their facility that require very different light depending on the work space. The ceilings in the office areas are lower, and employees are working on computers and conducting meetings, whereas in the production areas, the ceilings are much higher, employees are working on both large format machines as well as very fine detailed fabrication work, and the hours of light usage vary. These are just a few of the unique details that were considered when our TRC Lighting Experts developed a full re-design for each space that was custom fit to the needs of Crown Plastics, Inc.

“We just took a look at our overall lighting, mainly from our production areas, and they were all either running T8 or T12 fixtures, some metal halide…and they were failing. I was done switching them over. I didn’t want to do it one by one…I knew there had to be a better solution out there,” -Matt Van Beusekom.

3) “TO SAVE MONEY”

When our lighting expert LuAnn Verduzco met with Matt at Crown Plastics, Inc. to discuss his facility, she knew that this project would benefit from our expert level attention to detail, starting with a custom Investment Grade Audit. The full scope of work provided with this IGA showcased a proposed energy reduction of 45,584 kWh, or a nearly $5,000 annual savings just in energy costs. This is the equivalent of saving 30.2 acres of forest from deforestation in 1 year, or saving 70,647.6 lbs of CO2, which is the leading cause of global warming. This project not only provided Crown Plastics, Inc. with a 13.37% ROI, or a simple payback of 8.8 years, but it also had a significantly positive impact on the environment.

“To be honest, that was probably one of the biggest reasons why I chose to go this direction…being able to see the light output of each area, the recommended solutions and the reduction in energy costs, I felt more comfortable seeing the math behind it,” -Matt Van Beusekom

4) “TO SHOWCASE WHAT WE DO FOR OUR CUSTOMERS”

Having pride in your business and your services not only means you are confident in your results and your customer satisfaction, it also means you have invested in your facility; this is something that every business can relate to. When a business is proud to show their customers through their work space, showcasing their custom processes and their expert level in-house talent, the whole package comes together with a much stronger impact.

“We are a custom fabricator and distributor of plastic sheet rod and tube…what we do is really unique. 98% of what we do is driven by our customer demands; we are a custom job shop.” Matt Van Beusekom, Operations Manager at Crown Plastics, Inc.

Take a look at the video below to see how this project provided a complete transformation to the multiple work areas of Crown Plastics, Inc.

Customer Spotlight, Crown Plastics, Inc.LED Lighting Upgrade, Retrofit Light Fixtures, New LED Technology, Energy Savings, Investment Grade Audit