5 Ways Lighting Reduces Operating Costs

Published November 2019

Reducing Operational Costs Through Lighting Plans

By: Bret Wobschall

Despite cost savings being just one of the many benefits of an LED retrofit, it is typically the primary justification of an organization doing an LED retrofit. What many people don’t know is that there are still many cost savings that are not typically accounted for in payback scenarios, such as design and operational activities, that can lead to even further savings throughout the life of a lighting system.

I got my start in lighting as a customer implementing lighting projects at a manufacturing facility I was managing. Here are five cost saving factors I have successfully used when managing the replacement or maintenance of a lighting system.

Maximize the scope of a project.

Make replacement or maintenance projects as wide reaching as possible. If you can do an entire facility at one time rather than breaking it into multiple projects, it will likely have less of an overall impact on your operations as well as letting you purchase the project at a better price. Stopping or rearranging production schedules in a manufacturing environment (and others) can have major costs and effects on efficiencies, if projects and maintenance activities are broken into small portions it will create unnecessary additional breaks in production. This principal can be applied to full lighting system retrofits all the way down to something as simple as replacement of burnt out lamps. For lamp replacement you should estimate/monitor the lifespan of your lamps and schedule a full replacement at one time rather than replacing lamps as they burn out. You will end up replacing most equipment before it fails but the efficiencies gained through replacing everything at once, in my experience, have been proven to outweigh the costs of replacing one lamp at a time.

Minimize your opportunities for failure points.

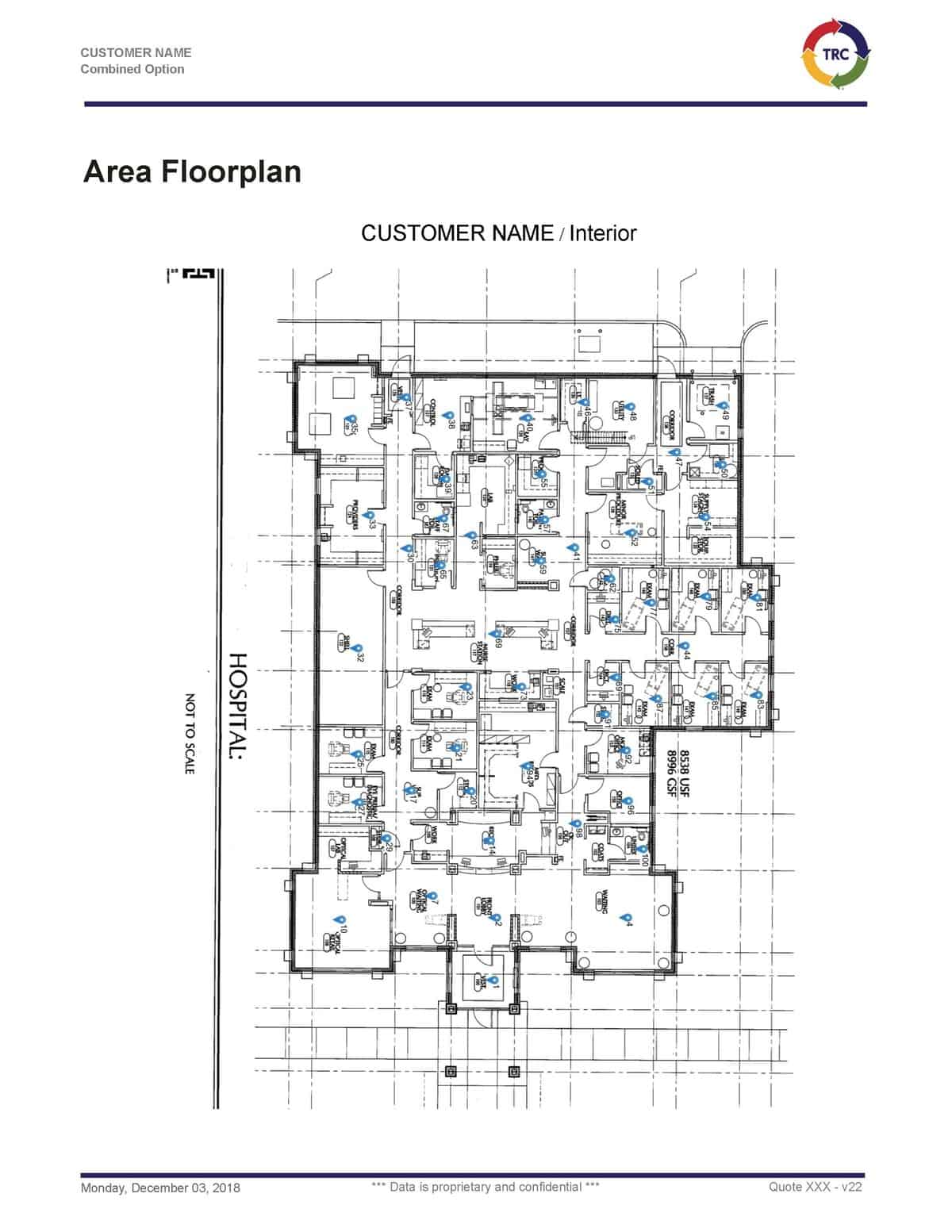

This rule can be applied to many things in a production plan, which includes your lighting system. The fewer pieces there are to a system the easier and quicker it is to maintain, which in turn keeps maintenance costs down. You need enough luminaires to create even light but there are situations when moving from other lighting technologies to LED that not as many luminaires are needed. A one for one LED replacement of an old system may mean installing more luminaires than would be needed with a properly designed lighting system. The fewer fixtures you must maintain the lower your maintenance costs will be.

Have lighting components that are serviceable.

Some LED luminaries are sealed or non-serviceable units. If you have a non-serviceable luminaire that fails, you will be forced to replace the entire unit rather than replacing a component. A new luminaire will cost more than a replacement component. Additionally, you may be left with a fixture that doesn’t match the rest of your lighting system. LED drivers do not have the same life span as the diodes and will typically need to be replaced over a luminaire’s life, so make sure you get a luminaire where it can be replaced.

Keep extra components and/or luminaires on hand.

If you have a lamp/driver/luminaire that must be serviced before a full scheduled system replacement you will cut labor and down time almost in half by having extra components on hand prior to troubleshooting an issue. Service calls and downtime can be expensive, and you will double up on those if the problem must be diagnosed in the field and then a return trip is needed to install new components. Keep stock on hand that can be quickly installed so diagnostic work on a failed/damaged luminaire can be done on a bench and only one service call/shutdown is required.

Design your lighting system to your maintenance plan/abilities.

Many components of a lighting system should only be serviced by electricians but if you don’t have an electrician on staff there are things you can do to internalize your lighting maintenance. In some applications luminaires can be installed with a cord and plug so they can simply be unplugged and replaced with a new luminaire. There are pros and cons to a cord and plug luminaires versus hard wired luminaires but if you want to be able to change or move fixtures without needing an electrician you may want to consider luminaires with plugs.

Fluorescent, HID and even some linear LED lamps have a ballast or driver that supplies the power to them. The ballast or driver can be a serviceable part of a fixture but typically requires an electrician. However, there are LED lamps for most applications where, once the fixture is retrofitted, the ballast/driver can be eliminated. Without a ballast/driver the lamp is powered directly by line voltage. Line voltage lamps can be changed out by maintenance staff as easy as changing an incandescent bulb in a fixture you have at home.

Do you need to further reduce your operating costs? Are you interested in learning more about these cost saving techniques? Always feel free to reach out with questions at 1-800-795-1230 or do a free consult with our lighting team (below).